Services

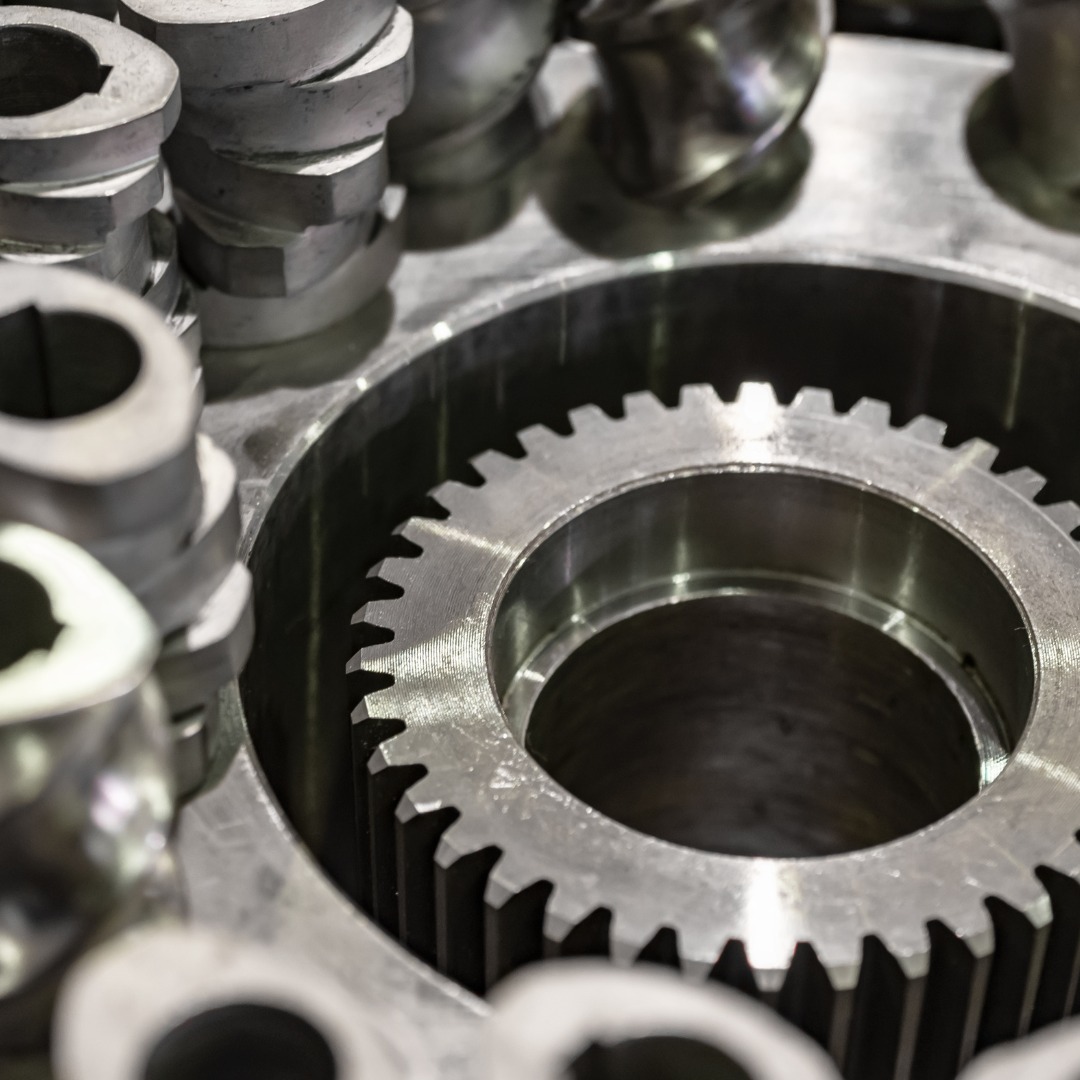

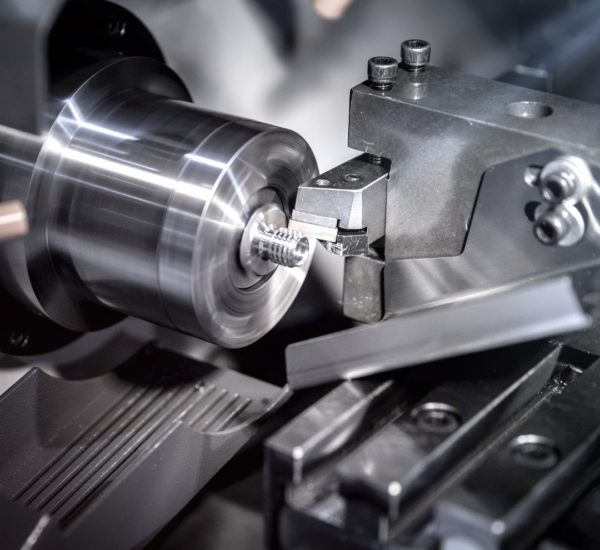

Precision Gear Manufacturing

We specialize in high-precision gears & machined components that require extremely precise movement and positioning.

Our Products

-

Worm Gears & Worm Gear Sets

Worm Gears & Worm Gear Sets -

External Spur Gears

External Spur Gears -

Helical Gears

Helical Gears

Patterson Gear manufactures worms, worm gears and worm gear sets for machinery, pump and agricultural industries, among many others. Use of the worm gear, which is similar to a standard spur gear, and the worm, allows for smaller gear boxes or drives, while retaining torque or power.

Our machining experience includes turning, thread milling, hobbing, and thread grinding – we can use any of these to produce your worms, worm gears and worm gear sets. We work with metals including ductile iron, carbon steel, stainless steel, brass, bronze and plastics. We also finish and heat treat parts.

Using milling, hobbing and shaping, Patterson Gear can cut your external spur gears in various sizes. We work with brass, bronze, aluminum, cast iron and various steels, as well as plastics. We serve customers in a wide range of industries, and we are ready to meet your custom spur gear requirements.

Patterson Gear serves industries ranging from agricultural machinery, bottling equipment and construction equipment, to food service equipment, lawn and garden equipment and more. In addition to our hobbing and milling capabilities, we offer finishing processes for our helical gears. We heat treating in house and have plating vendors for nickel & hard chrome. We manufacture in volumes from prototype up through production runs, with just-in-time deliveries available. Contact us for lead times and a quote

-

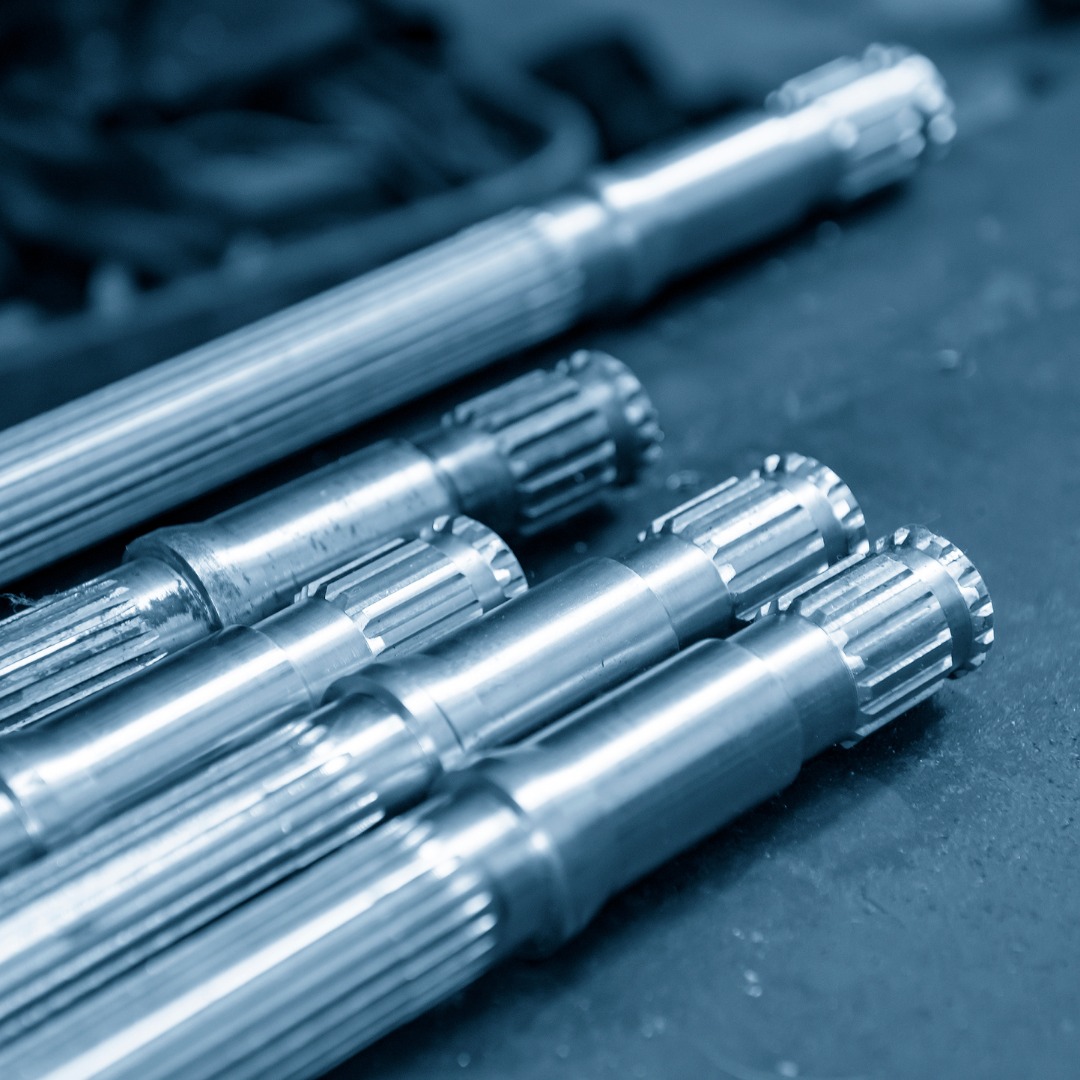

External Splines

External Splines -

Keyways and Broaching Services

Keyways and Broaching Services -

Sprocket Gears

Sprocket Gears

With a variety of machining options including hobbing, shaping and broaching, Patterson Gears is adept at cutting external involute and straight-sided splines on workpieces. We work with metals such as gray cast iron, alloy steel, aluminum and stainless steel.

Patterson Gear offers an efficient way to machine keyways. Precision is of utmost importance in shaping and broaching operations, and our facility is well-equipped to handle these requirements. We offer two related services: shaping and broaching, each with similar properties but slightly different capacities.

We work with a wide variety of materials: metals such as alloy steel, aluminum, carbon steel and ductile iron, as well as plastics, phenolics and Delrin.

We provide broaching and shaping services for industries such as machinery, medical, optical, packaging, construction and many more, and we produce short or long runs.

Patterson Gear offers sprocket manufacturing services, using our machining capabilities including conventional hobbing.

When required, we can also heat treat sprockets. We work with a full range of materials, metal to plastic, from aluminum to stainless steel.

Our production shop accepts jobs from prototype and short runs, all the way up to large-scale production runs.

Contact us with your project requirements for more information.

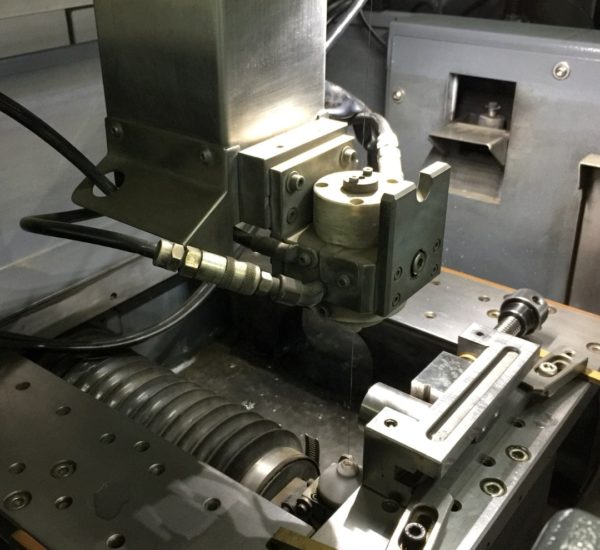

CNC Milling

We support 3-axis, 4-axis milling, and right angle milling capabilities to help you rapidly create designs from simple straight lines to complex geometric shapes.

CNC Turning

We can deliver high-quality metal or plastic turned parts for rapid prototyping or production, while also delivering the most competitive pricing and lead times.

Grinding Services

Outside Diameter/OD grinding 24” long x 6” diameter. Surface grinding 12.0” x 40” long tolerance to .020mm

EDM Services

Wire EDM and sinker EDM services. 4th axis wire EDM up to 35deg x 3.0” height.